concrete scanning

GPR Scanning in

ATHEns, GA

ATHENS GPR Scanning Services

Ground Penetrating Radar (GPR) is a non-invasive technology used to image the subsurface. It’s widely applied in industries like construction, archaeology, geology, and environmental studies. GPR operates by sending electromagnetic waves into the ground and measuring the reflected signals that return from underground objects or material boundaries.

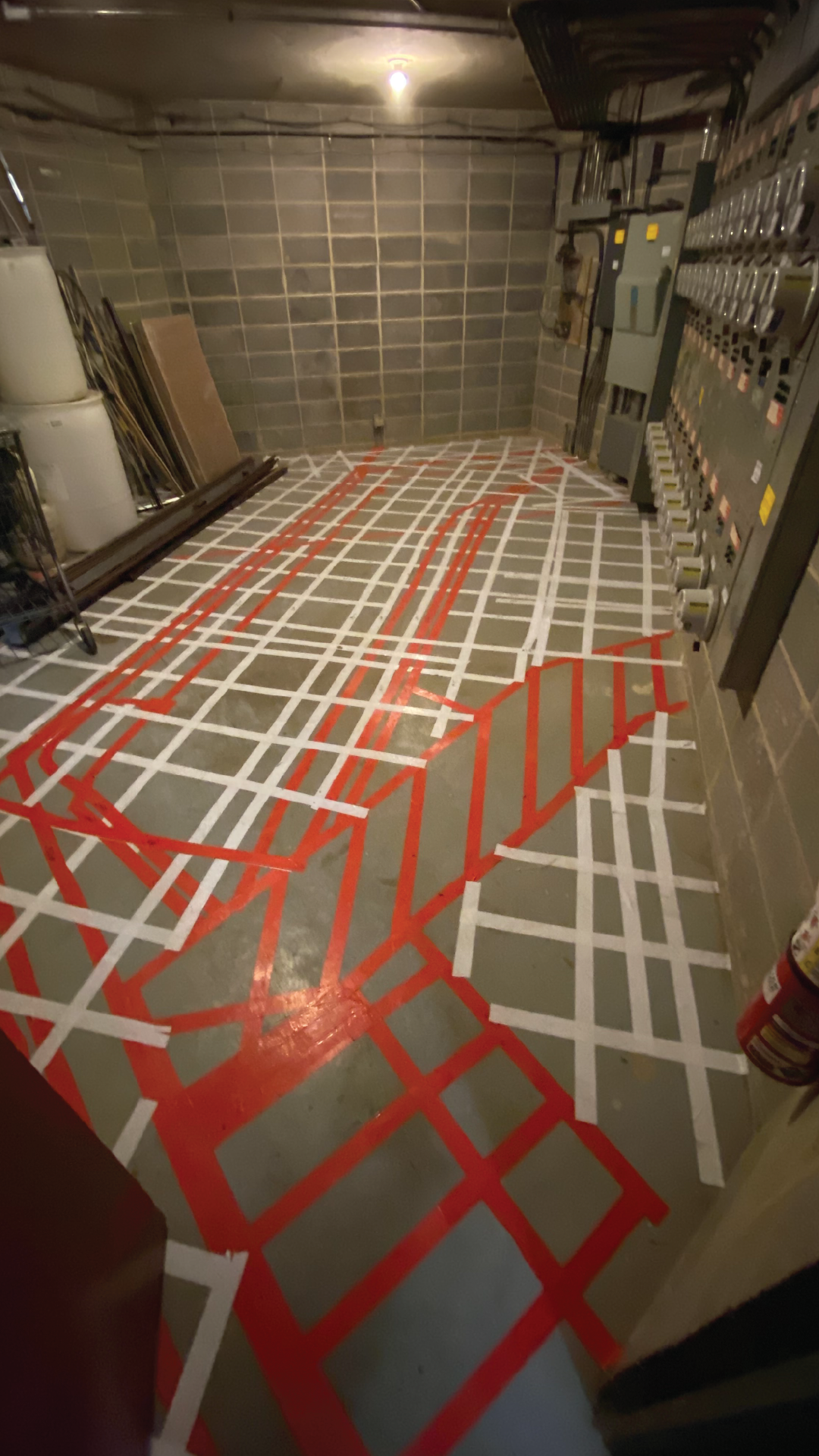

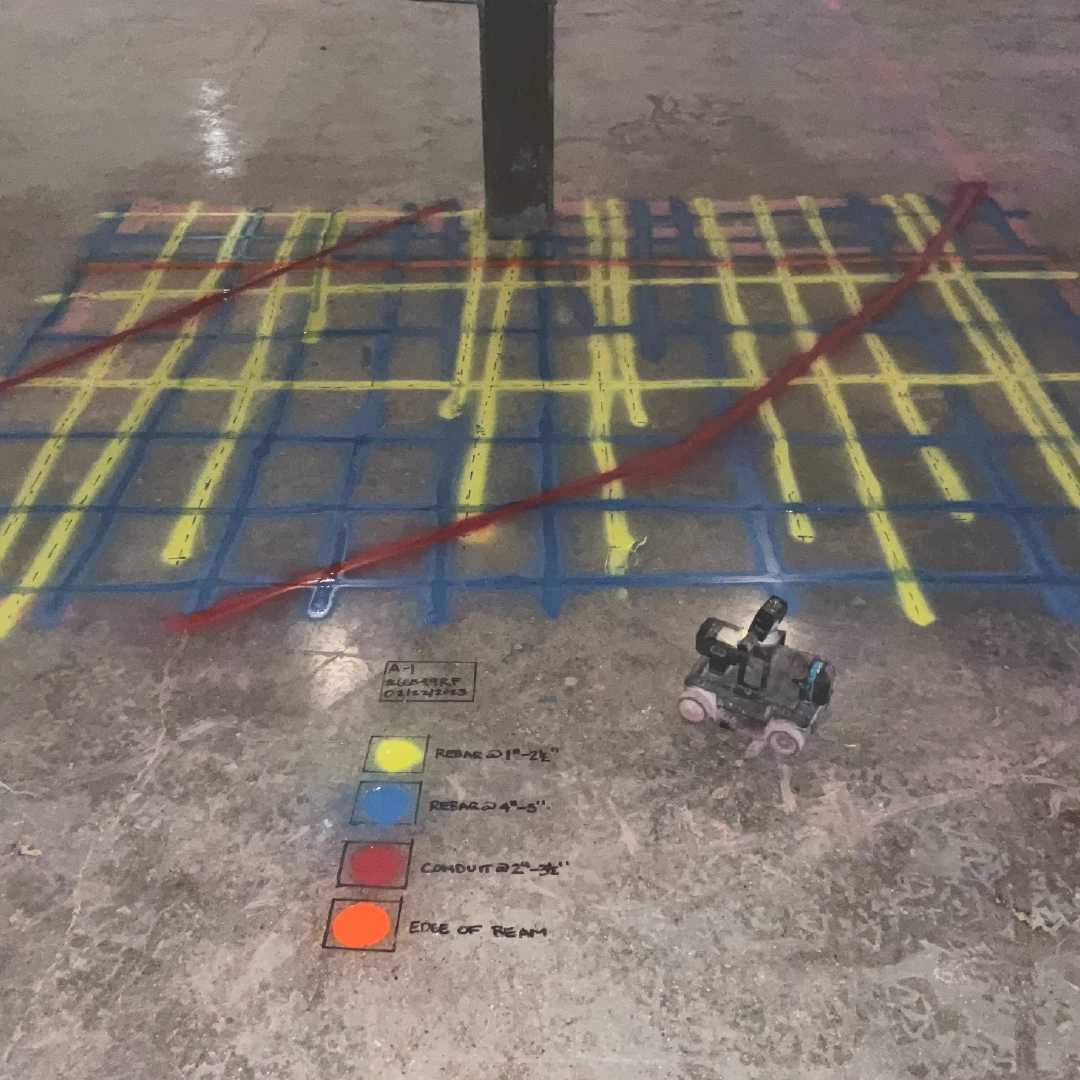

In Athens, GA, GPR is essential for non-destructive testing on concrete, soil, and asphalt. This technology can detect utilities, rebar, voids, and other subsurface features without disturbing the surface.

GPR systems consist of a control unit, an antenna, and a display. The antenna emits and receives radar waves, while the control unit processes the signals. The display provides real-time visualizations of what lies beneath the surface, allowing for accurate and efficient analysis.

Why GPR Investigations are Essential Before Concrete Cutting

Performing a GPR scan before any concrete cutting project in Athens, GA, is essential for both safety and efficiency.

At Cobra Southeast, we use GPR technology to detect concealed elements like rebar, electrical conduits, and post-tension cables within concrete structures. Identifying these hidden features helps avoid accidental hits that could lead to damage, costly repairs, or project delays. Additionally, GPR provides critical data that enables more accurate planning, ensuring your construction project runs smoothly and on schedule.

A Ground Penetrating Radar (GPR) survey is conducted using the following steps:

It is important to note that conducting a GPR survey requires expertise in data interpretation and knowledge of the subsurface conditions. Professional geophysicists or surveyors are typically involved in performing and analyzing GPR surveys.

Applications of GPR Concrete Scanning

GPR concrete scanning is useful for a variety of construction and renovation projects. At Cobra Southeast, we utilize this advanced technology for several key applications:

What Can GPR Detect?

Ground Penetrating Radar (GPR) is a versatile tool used in construction projects. At Cobra Southeast, our advanced GPR technology can detect various subsurface elements, including:

Service Specs:

Depth

Up to 16"-36" depending on site conditions

Type of Cut

Typical Depth Penetration

Materials Cut

Concrete, Rebar

Powered By

Rechargeable Ni-Cd or Li-io Rechargeable batteries

Receive a FREE Quote On Your Next Job

We pride ourselves on our commitment to complete client satisfaction and safety, and we have the reputation and track record to prove it.

Why ATHENS Trusts Us

Businesses and contractors across Georgia trust Cobra Southeast for dependable GPR scanning services because we prioritize building strong, lasting relationships with our clients. We know the importance of trust and open communication, which is why we collaborate closely with you to meet the unique demands of your project. Our commitment to safety and cutting-edge technology ensures each scan is performed with the highest level of accuracy and care, giving you the confidence and peace of mind necessary to move forward smoothly. When precision matters, Athens chooses Cobra Southeast.

Safety

At Cobra Southeast, safety is our top priority from the beginning to the end of every project. We take every precaution to protect our team, clients, and infrastructure, ensuring a secure work environment throughout the entire process.

Relationships

We believe in building strong, lasting relationships with our clients. By fostering trust and maintaining clear communication, we ensure the success of every project and establish partnerships that extend beyond completion.

Innovation

We are committed to finding better solutions and implementing innovative ideas to complete projects more efficiently. Our focus on cutting-edge technology and processes allows us to deliver high-quality results on time.

gpr concrete scanning FAQs

We've compiled this comprehensive list of frequently asked questions to provide you with quick and informative answers. Whether you're a new customer seeking information about our offerings or a returning customer with inquiries about using our platform, you'll find valuable insights here.

Request a Quote

Thank you for your interest in our services! We pride ourselves on our commitment to complete client satisfaction and safety, and we have the reputation and track record to prove it.