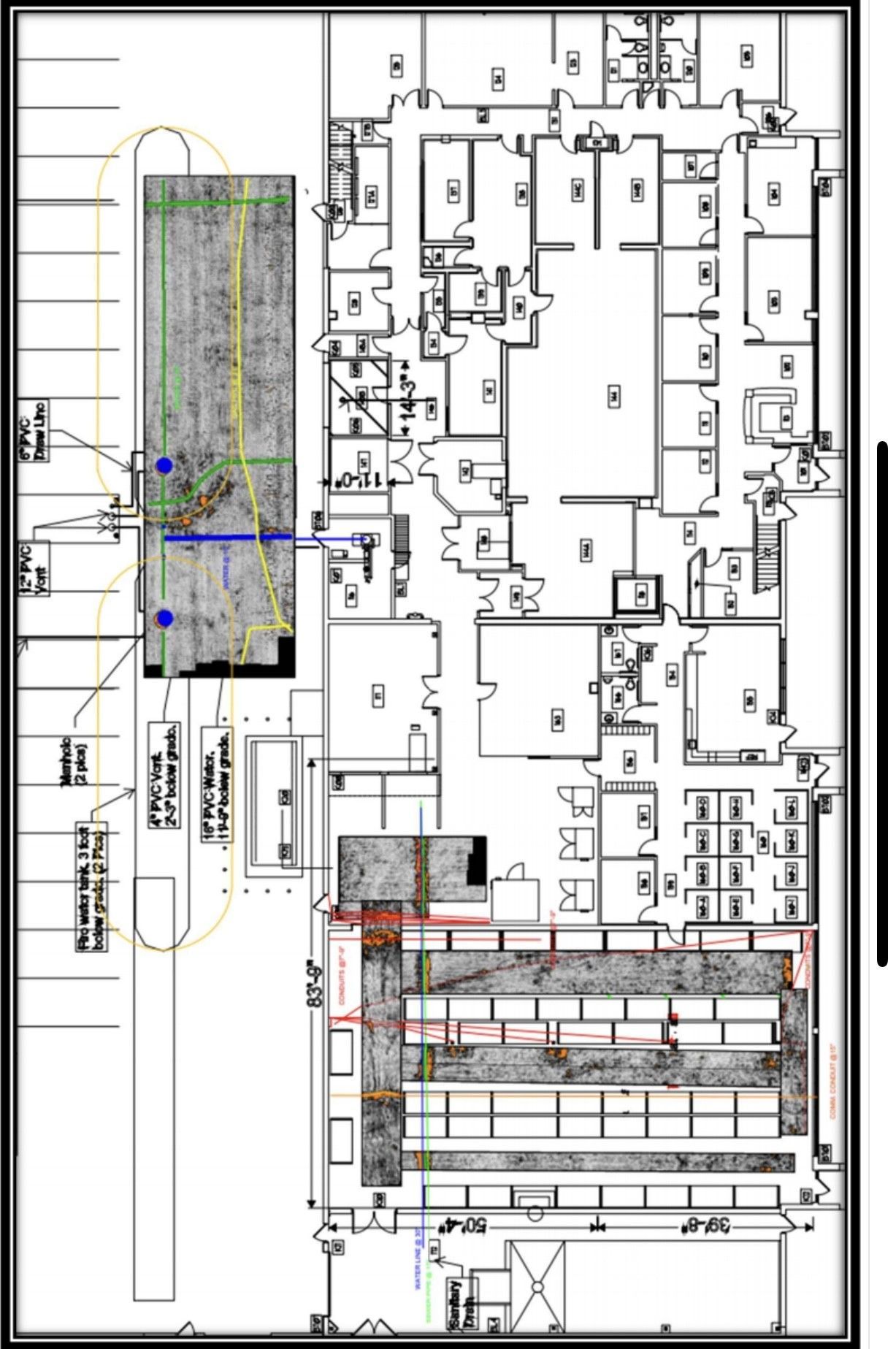

concrete scanning

Private EM and GPR Utility Locating in Atlanta

Underground Utility Locating

Utility locating is the process of identifying and marking the underground utilities such as water pipes, gas lines, electrical cables, and telecommunications cables. This is done to prevent accidental damage to these utilities during construction or excavation projects.

Utility locating is typically performed using specialized EM and GPR equipment to accurately locate and mark the utilities' positions. This helps ensure the safety of workers and the integrity of the utilities.

Cobra can perform the following types of locates:

- Private Utilities: Private utilities are utility lines that are not owned or maintained by the public utility companies. These can include lines for private water, sewer, gas, or electrical systems. To locate private utilities, you may need to hire a private utility locating company or consult with a professional surveyor who specializes in private utility locates.

- Secondary Utilities: Secondary utilities are utility lines that are not considered primary or essential services but still need to be located before excavation. These can include lines for irrigation systems, landscape lighting, or private communication lines. Contact the relevant service providers or consult with a professional to locate these secondary utilities.

Where We Work

We have 4 locations spanning the Southeast. Find out more about each location and how to contact us.

atlanta

jacksonville

tampa

chattanooga

nashville

Utility Locating Experts

During a concrete bridge deck inspection, several key areas are thoroughly inspected to assess the condition and integrity of the structure. These areas typically include:

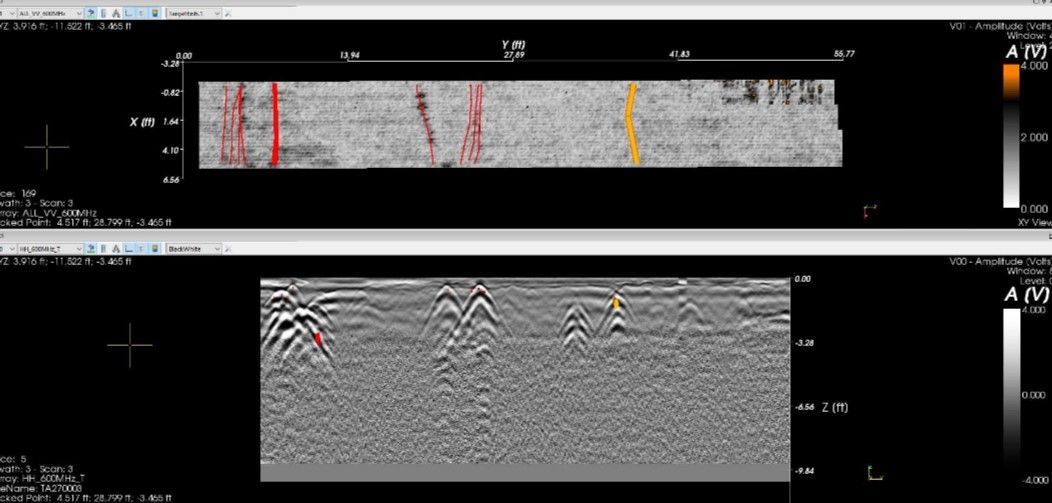

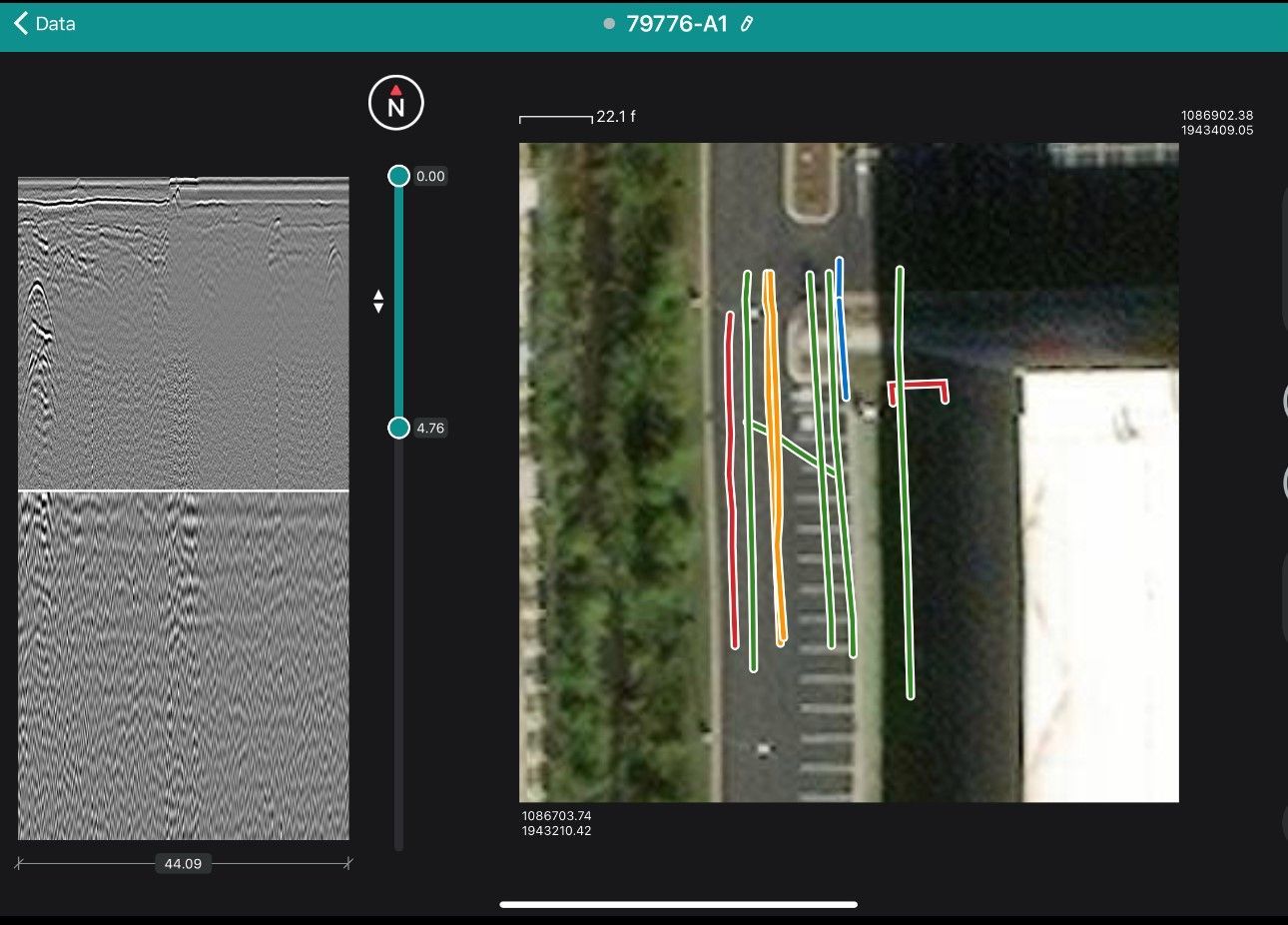

stream c- multi channel gpr

To obtain the highest level of certainty when performing a Utility Locate, a Multi-Channel GPR unit can be used. The power of the system is that it can collect data in both directions with one pass. It can also locate trenches, voids, and buried train tracks.

Service Specs:

em locate Depth

10' or greater

Type of Cut

Straight Cut

Materials Cut

Concrete, Asphalt, Soil, Gravel etc.

Powered By

Ni/Cd or Li-ion battery

Dust control method

Yes

Best For:

Locating private utilities, buried tanks, unmarked graves, tree root systems, etc.

Receive a FREE Quote On Your Next Job

We pride ourselves on our commitment to complete client satisfaction and safety, and we have the reputation and track record to prove it.

Why Choose Us

We revolutionize the concrete sawing & drilling industry through our innovation & attitude, provide a level of service & passion that our customers, our employees & our community desire to experience.

Safety

Cobra emphasizes the importance of safety from start to finish of every project.

Relationships

Creating successful relationships while building trust during completion of all current projects and beyond.

Innovation

Better solutions and ideas to complete projects in a more timely and efficient manner.

bridge deck inspection FAQs

These FAQs provide a basic understanding of concrete bridge deck inspections and their importance in maintaining the safety and functionality of bridge structures. Specific details may vary based on the location and type of bridge.

Request a Quote

Thank you for your interest in our services! We pride ourselves on our commitment to complete client satisfaction and safety, and we have the reputation and track record to prove it.