Written by: Cobra Concrete Southeast

Concrete construction and excavation projects require more than just tools and manpower—they require precision, safety, and reliable data. Whether you're cutting through concrete, excavating a site, or scanning for buried utilities, Ground Penetrating Radar (GPR) is a game-changer. It’s a cutting-edge technology that has revolutionized how contractors locate utilities, map subsurfaces, and safely execute projects.

What is Ground Penetrating Radar (GPR)?

Ground Penetrating Radar, commonly known as GPR, is a non-invasive technology used to scan beneath the surface of the ground or concrete. It sends electromagnetic waves into a material—such as soil, concrete, or rock—and captures the reflections of these waves to create a detailed image of what lies beneath.

Unlike traditional excavation or destructive methods, GPR allows contractors to identify buried utilities, voids, rebar, post-tension cables, and other subsurface structures without damaging the material being scanned. In short, GPR lets you see what’s hidden before you start digging, cutting, or drilling.

How Does GPR Work?

At its core, GPR operates by transmitting high-frequency radio waves into the ground or a material. Here’s a step-by-step breakdown of how it works:

- Transmission: A GPR antenna emits electromagnetic waves.

- Reflection: These waves travel through the subsurface and bounce back when they hit an object or material with different properties, such as metal, plastic, or voids.

- Detection: The reflected waves are captured by the GPR equipment.

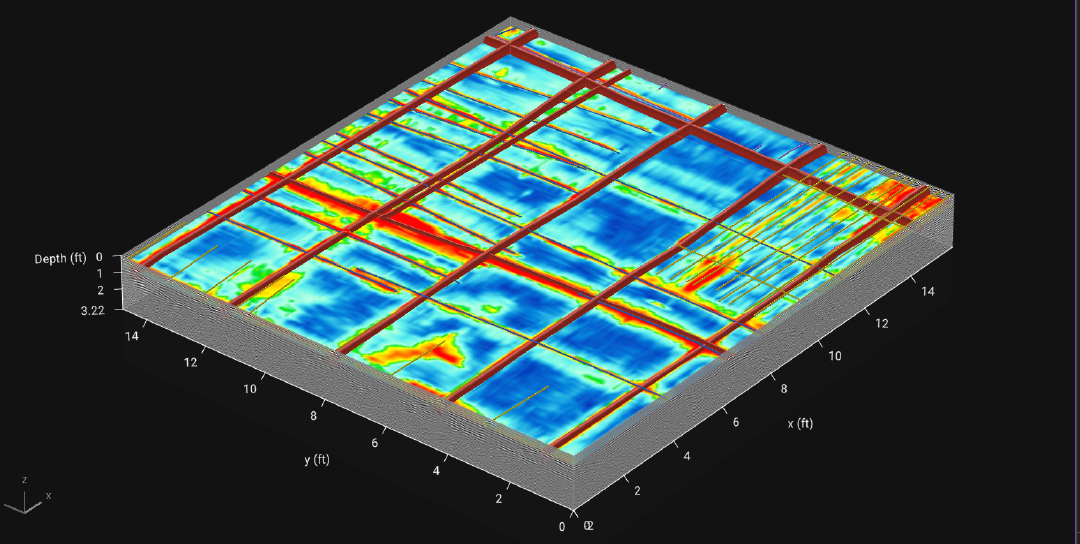

- Data Processing: The equipment processes the reflections into readable data, which is displayed as a 2D or 3D image.

- GPR provides accurate, real-time information, making it an invaluable tool for pre-construction planning, utility locating, and excavation.

Equipment

GPR systems consist of three main components:

- Control Unit: This is essentially the brain of the system, managing the transmission of electromagnetic waves and interpreting the reflected signals.

- Antenna: The antenna determines the depth and resolution of the scan. High-frequency antennas provide more detail but less depth, while low-frequency antennas penetrate deeper but offer less resolution.

- Display Monitor: The display provides a visual representation of the data, helping operators interpret what’s below the surface.

Modern GPR systems are portable, rugged, and capable of handling various site conditions, from urban environments to rugged outdoor terrain.

Methods

The success of a GPR survey depends on using the right methods. A few key techniques include:

- Grid Scanning: This involves scanning a grid pattern to create a detailed map of a specific area.

- Spot Scanning: Used for quick checks in smaller areas or for identifying specific targets.

- Continuous Scanning: Best for linear surveys like roads, pipelines, or walls.

Operators must also consider soil type, moisture levels, and the target depth to achieve optimal results.

Data

The raw data collected by GPR equipment consists of wave reflections, but trained operators can process this data into clear, actionable insights. Data is typically displayed as:

- 2D Scans: These show a cross-sectional view of the subsurface.

- 3D Models: Advanced systems can create detailed 3D maps for complex projects.

The clarity and accuracy of GPR data depend on the expertise of the operator and the quality of the equipment. At Cobra Southeast, our GPR specialists are trained to deliver precise results that help your project stay on track and within budget.

What Can GPR Detect?

GPR is highly versatile, capable of detecting a variety of subsurface features, including:

- Metal Objects: Rebar, post-tension cables, and pipes.

- Non-Metal Objects: Plastic pipes, voids, and buried utilities.

- Soil Disturbances: Such as trenches, tunnels, or graves.

- Concrete Features: Slabs, thickness variations, and internal voids.

- Utilities: Water lines, sewer lines, and electrical conduits.

This versatility makes GPR an essential tool for construction, demolition, and engineering projects.

Applications of Ground Penetrating Radar

Utility Locating

One of the most common uses of GPR is identifying and mapping underground utilities. Whether you’re locating water lines, gas lines, or electrical conduits, GPR eliminates guesswork, reducing the risk of costly damage and downtime.

Subsurface Mapping

For large construction projects, understanding the subsurface conditions is critical. GPR can map soil layers, detect underground voids, and identify obstacles that could impact excavation.

Excavating

Before breaking ground, GPR ensures the area is clear of hidden hazards. It’s especially useful in urban environments where utility congestion is common.

Benefits of Using GPR

- Non-Destructive: No drilling or digging is required, saving time and resources.

- Safe: Avoids striking buried utilities or structures, reducing safety risks.

- Accurate: Provides detailed, real-time data for better decision-making.

- Cost-Effective: Prevents costly repairs, delays, and rework.

- Versatile: Works in a variety of materials and conditions.

Whether you’re a general contractor, engineer, or municipality, GPR is an investment in the safety and efficiency of your projects.

Should You Buy GPR Equipment or Hire Professionals?

If you’re considering adding GPR to your toolbox, it’s important to weigh the costs and expertise required. While owning GPR equipment may seem convenient, it comes with challenges:

- Cost: GPR systems can be expensive, especially for advanced models.

- Training: Interpreting GPR data requires specialized knowledge and experience.

- Maintenance: Keeping equipment in optimal condition can be time-consuming.

For most contractors, hiring GPR professionals like Cobra Southeast is the smarter choice. Our team has the experience, equipment, and expertise to handle your scanning needs, ensuring fast, accurate results without the headache.

Reach Out to Cobra About Your Next Project!

At Cobra Southeast, we specialize in GPR scanning for a wide range of industries, including healthcare, infrastructure, and commercial construction. Our team is dedicated to delivering precise, reliable results that keep your project safe, efficient, and on schedule.

Ready to get started?

Contact us today to learn more about our GPR services or to schedule a consultation. Let us show you why we’re the trusted experts in concrete scanning, cutting, and demolition.

Southeast

119 Gateway Dr. #110

Canton, GA 30115

(770) 599-2098

Website imagined and executed by RivalMind.